MACHINING

TRANSMISSION PARTS:

ZFPL has, over the course of the last decade, built appreciable capacities to cut and finish transmission parts, particularly in the 4-5 module range. Catering primarily to the commercial vehicle segment, our gears are cut within extremely precise and critical tolerances upto DIN 6 levels. Our gear cutting department is equipped with state-of-the-art gear cutting machines from Liebherr, Gleason-Pfauter, Prawema, Arthur Klink, Lorenz, Forst, Kanzaki, Hurth, and other renowned manufacturers of gear cutting equipment.

Broadly, our transmission business is segmented into 3 product families, each of which have their own manufacturing lines in our Machining Unit:

- Parallel Axis Cylindrical Gears

– CNC turning

-CNC Hobbing for external gears

– CNC Gear shaping for dog-teeth and internal splines

-CNC Dual chamfering

-Milling/Drilling of oil pockets for lubrication

-Gear Shaving or Gear Grinding

-Bore/ID Grinding or Hard part turning

-Bore honing - Synchroniser Parts (Cones, Hubs, and Sleeves)

– CNC Turning

– Internal Spline Broaching

– For Sleeves- combination machining of shifter stops, roofing/tooth chamfering, and oil pocket milling within the internal spline on Prawema machine

– Tooth chamfering on Prawema SFSL2-1/R machines

– Oil pocket milling/Crescent milling for lubrication within gear shifting mechanism

– Slotting/Milling of synchro hubs for indent spring fitment, used during gear shifting - Transmission Shafts (Mainshaft, Layshaft, Input shaft)

– CNC Turning

– Deep hole drilling for throughout lubrication of 9S Mainshaft

-CNC Hobbing on 6 Axis gear cutting equipment

– CNC Gear Shaping for external splines

– Linear and angular drills for lubration

– Dual chamfering of gear teeth

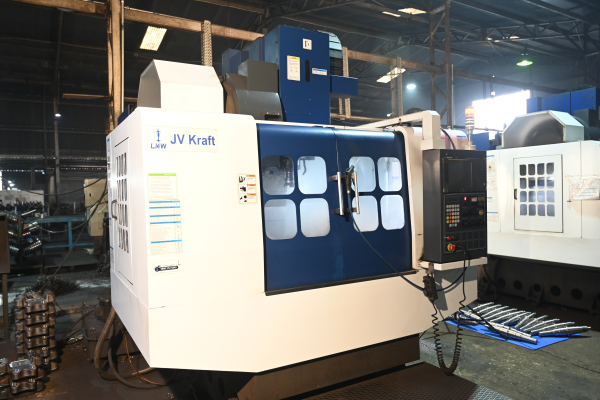

AXLE, ENGINE AND GENERAL ENGINEERING PARTS:

While the primary focus of ZFPL has always been in the transmission vertical, in 2011 we seized the opportunity to develop some parts in the axle and engine segments as well- which has grown appreciably over the years. Coupled with the addition of some general engineering product lines to renowned PSU’s, our vision of diversifying our portfolio to 25% in non-transmission verticals by 2024 remains intact!

The machining for these family of parts usually involves, 3 axis, 4 axis or 5-axis machining on vertical, horizontal, or universal machining centres. This family of parts comprises the following:

- Engine Pitman arms

- Steering Arms and Levers

- Track Rod Levers

- Axle support sleeves

- Axle Helical Gears

- Tie Rod Arms

- Relay Arms

- Male Eye Lugs